UH 60 Parts Magazine: Comprehensive Checklist of Elements

UH 60 Parts Magazine: Comprehensive Checklist of Elements

Blog Article

The Significance of Appropriately Sourcing UH-60 Components for Safe and Reliable Operations

The value of correctly sourcing UH-60 components can not be overstated, as the honesty and safety of aeronautics operations hinge on the high quality of these parts. Using qualified components not only makes sure conformity with rigorous engineering standards but also minimizes the dangers connected with low quality options.

Recognizing UH-60 Component Specifications

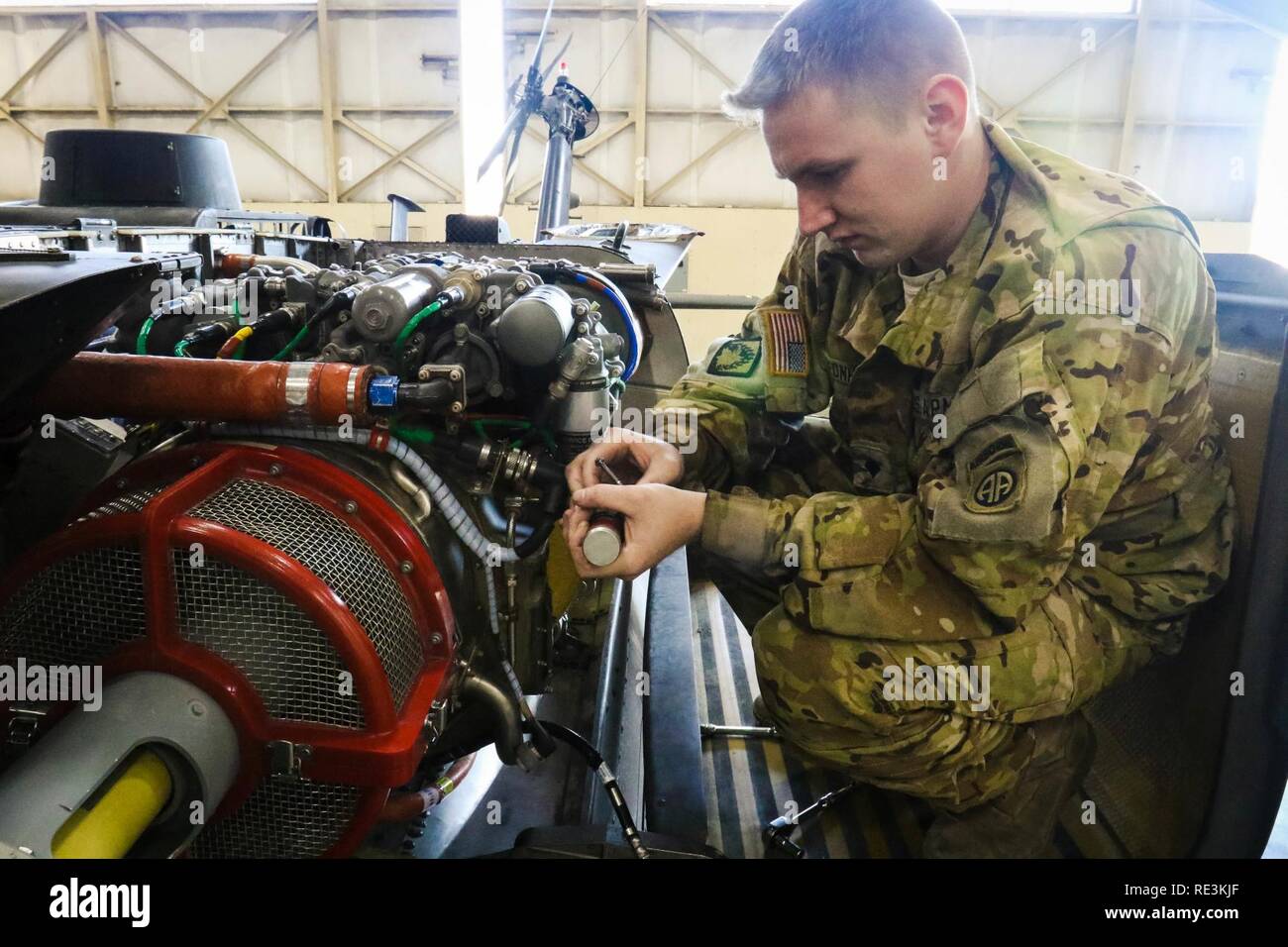

Recognizing the complexities of UH-60 component specifications is important for ensuring operational efficiency and safety in air travel upkeep. The UH-60, widely utilized in private and armed forces applications, requires components that meet stringent engineering and regulatory criteria. Each part is meticulously developed to carry out under particular conditions, and inconsistencies in requirements can bring about efficiency failings or security threats.

Component specs encompass various features, including product make-up, dimensional resistances, and operational thresholds. For instance, rotor blades must follow precise weight and aerodynamic accounts to assure optimal trip attributes. Additionally, components must go through extensive testing to confirm their dependability and longevity within the requiring settings normal of aviation procedures.

Moreover, comprehending the accreditation processes linked with UH-60 elements is essential. Each component may bear markings suggesting compliance with army or industry requirements, making sure that it has undertaken the required examinations and high quality evaluations. This compliance not just safeguards the aircraft's performance yet also cultivates responsibility among vendors and manufacturers. Consequently, comprehensive expertise of part specs is vital for maintenance personnel, allowing them to determine genuine components and maintain the functional honesty of the UH-60 fleet.

Risks of Using Substandard Parts

The honesty of air travel procedures depends upon the high quality of components used in airplane maintenance, especially for the UH-60. Using second-rate components presents considerable dangers that can jeopardize both safety and operational efficiency. These components might not fulfill the rigorous criteria established for army aeronautics, bring about unpredictable efficiency and prospective system failures.

Substandard parts can cause raised damage on crucial systems, ultimately reducing the life-span of the aircraft and necessitating expensive repair services or replacements. Additionally, using substandard materials may bring about disastrous failures throughout flight, jeopardizing the lives of staff participants and passengers alike.

Furthermore, dependence on non-compliant components can reveal drivers to lawful and governing consequences, as aircraft must stick to strict standards set forth by controling bodies. This can lead to grounding of the aircraft and significant operational delays.

Benefits of Certified Components

Qualified elements provide a wide range of benefits that considerably enhance the safety and integrity of UH-60 operations - uh 60 parts. One of the key benefits of these elements is their adherence to stringent high quality requirements. Certification procedures ensure that each component has actually undergone strenuous testing and examination, thereby verifying its efficiency and resilience under numerous operational conditions

The assimilation of qualified parts additionally promotes smoother upkeep treatments. Professionals can be positive in the dependability of these parts, decreasing the chance of unexpected fixings and boosting overall functional effectiveness. The lasting cost-effectiveness of licensed elements can not be overstated; while they might come at a higher first cost, their reliability and performance translate right into lower upkeep and replacement expenses over time. Eventually, buying licensed parts is crucial for the risk-free and effective procedure of UH-60 aircraft.

Sourcing From Respectable Vendors

When sourcing components for UH-60 aircraft, partnering with respectable distributors is important to guaranteeing quality and integrity. The safety and performance of armed forces airplane depend dramatically on the stability of their parts, making it vital to pick distributors with a proven record in the industry. Trusted vendors stick to rigorous quality control procedures and often hold appropriate accreditations, which act as a testimony to their commitment to excellence.

In addition to quality control, established suppliers give thorough support solutions, including technical help, guarantee programs, and timely shipment. This level of interaction is important for preserving functional readiness and reducing downtime. Furthermore, credible suppliers are usually a lot more transparent about their sourcing practices, ensuring that the parts supplied meet strict governing standards and more are compatible with check here existing systems.

It is also valuable to think about providers that focus on UH-60 parts, as they possess comprehensive understanding of the aircraft's requirements and requirements. By leveraging the experience of these vendors, operators can improve the security and efficiency of their procedures, ultimately causing improved mission success. Spending time in sourcing from credible providers is a critical step towards attaining optimal efficiency in UH-60 airplane operations - uh 60 parts.

Long-Term Expense Effectiveness

Accomplishing lasting expense performance in sourcing UH-60 components needs a tactical strategy that balances first financial investment with continuous functional costs. Organizations needs to prioritize quality over rate, as substandard parts may bring about regular fixings and boosted downtime, ultimately blowing up general costs. By purchasing reputable, certified elements, operators can improve the aircraft's efficiency and longevity, minimizing the risk of unforeseen failings.

In addition, developing lasting connections with reliable distributors can produce financial advantages, such as bulk acquiring discounts and positive settlement terms. These partnerships help with access to exceptional items and technical support, making certain that the sourcing process lines up with operational requirements and governing standards.

Additionally, implementing a methodical stock monitoring method check out here permits much better projecting of component needs, reducing excess stock and connected holding prices. On a regular basis reviewing provider performance and part integrity can also inform future getting choices, making it possible for organizations to adjust to advancing functional needs successfully.

Ultimately, a focus on long-term expense effectiveness in sourcing UH-60 components not just safeguards operational stability however additionally adds to an extra lasting monetary design, permitting reinvestment in important air travel capacities.

Conclusion

In conclusion, the correct sourcing of UH-60 parts is important for preserving efficient and risk-free aeronautics operations. Sticking to stringent requirements and using qualified elements mitigates the dangers linked with subpar parts.

The value of correctly sourcing UH-60 components can not be overstated, as the stability and safety of aeronautics operations hinge on the top quality of these components.Comprehending the details of UH-60 component specifications is crucial for making certain operational performance and safety and security in aviation maintenance. Thorough understanding of component specifications is vital for upkeep personnel, enabling them to determine genuine parts and preserve the functional honesty of the UH-60 fleet.

When sourcing components for UH-60 airplane, partnering with respectable suppliers is important to ensuring quality and reliability.Accomplishing long-lasting expense performance in sourcing UH-60 parts calls for a strategic approach that balances initial investment with recurring operational expenses.

Report this page